Grip Stone

Grip Stone - ROUGH COAT ON MARBLE, GRANITE FOR BETTER GRIP

Reason for Introducing Grip Stone

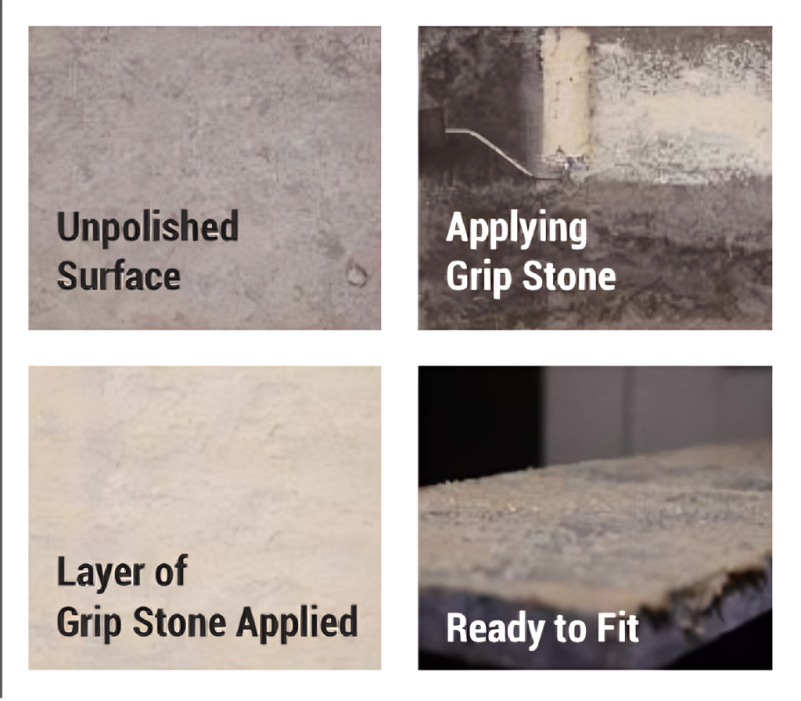

Looking at the current scenario of the construction industry, in the market, the use of Marble, Granite, etc is growing very fast, but while fitting this, for better grip we need to rough the unpolished surface. Today everyone is trying different ways to rough the unpolished surface, sometimes it is successful, and sometimes it fails, resulting in the de-bonding of Marble, Granite, etc, and damage of costly material. Adhesion of Marbles, Granite, Tiles, and stone, to smooth or even rough surfaces is always doubtful. Till today there is no specific product that can be used for roughening the unpolished surface and improving bonding. To address changing trends and issues of de-bonding, we have introduced innovative specially formulated products for roughening and improved bonding of the unpolished surface.

Reason for Introducing Grip Stone

Looking at the current scenario of the construction industry, in the market, the use of Marble, Granite, etc is growing very fast, but while fitting this, for better grip we need to rough the unpolished surface. Today everyone is trying different ways to rough the unpolished surface, sometimes it is successful, and sometimes it fails, resulting in the de-bonding of Marble, Granite, etc, and damage of costly material. Adhesion of Marbles, Granite, Tiles, and stone, to smooth or even rough surfaces is always doubtful. Till today there is no specific product that can be used for roughening the unpolished surface and improving bonding. To address changing trends and issues of de-bonding, we have introduced innovative specially formulated products for roughening and improved bonding of the unpolished surface.

Reason for Introducing Grip Stone

• Ready to apply?

• Contains fine aggregates to impart a better mechanical bond. Grip Stone is the only bonding agent that imparts both mechanical and chemical bonds.

a. Mechanical Bond – Imparted by the suspended fine aggregates, which are inert, screened on a 500-micron sieve, Pure white.

b. Chemical Bond–Imparted by dry polymeric film.

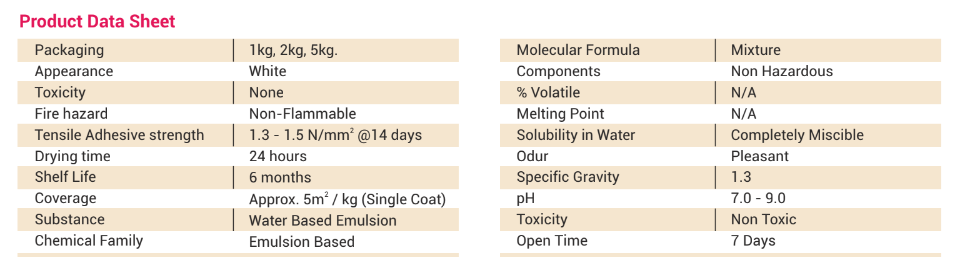

Coverage

• Approximate Coverage would be 05 Sq Mtr. per Kg.,(Single Coat).

• Depends Upon the background surface and its suction properties.

Application

1. Recommended cleaning methods are high-pressure water jets and (or) soap washing.

2. Open the original packing and stir it properly.

3. Do not dilute with water or solvent.

4. Do not add any admixture

5. Grip Stone can be applied with a paint roller or paint brush, and it shall be pressed firmly against the surface and spread thin and evenly.

6. Apply Grip Stone to the cleaned surface evenly, then clean all edges and remove excess material.

7. Thin continuous unbroken film is recommended.

8. Allow Grip Stone to dry for Approximately 24 hours of drying time.

9. After drying don’t pull the film formed.

10. Can be fitted with cement or suitable product.